MRP is a process that enables business meet there material requirement. It not only makes sure that materials are available for production but also schedules the proposals for the procurement by calculating lead time

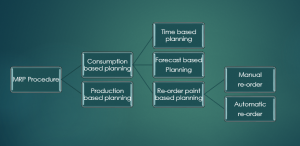

Material requirement planning is done at plant level and planned order is generated if the infrastructure is available it is manufactured internally else it is converted to purchase requisition further to purchase order, Storage location, Subcontracts are inspected before ordering. Material requirement planning is widely used in automobile industry. MRP offers wide variety of planning flexibility

There are three different planning runs in SAP

NEUPL-Regenerative planning: in this type of planning complete list of components that in the planning file are planned irrespective of there requirement

NETCH-Net change planning in total horizon: Components that are marked with NECTH indicator are planned. Components that under go certain change with respect to quantity are planned

NETPL-Net change planning in horizon: Only the components that are marked with NETPL are planned